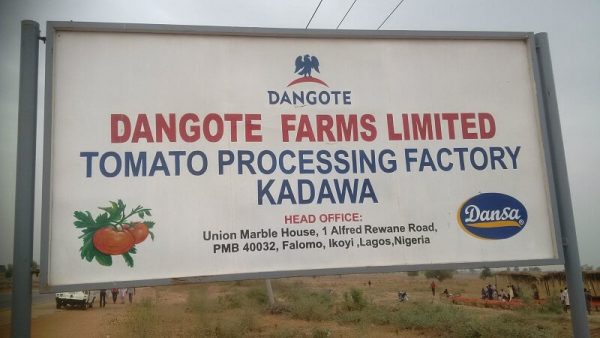

The Dangote tomato processing factory located in Kano was closed after the farmers committed to supplying the factory with raw materials that abandoned the cultivation of tomatoes at the beginning of the rainy season in May.

The factory resumed operations in March after being inactive for three years. According to Abdulkareem Kaita, managing director of Dangote Farms, the company is losing at least N30 million every month of closure.

The factory, which is the largest in Nigeria, has the capacity to process 1,200 tons of tomatoes per day. The plant needs about 40 trucks of fresh tomatoes a day and each truck handles 30 tons of products.

Dangote launched the company in March 2016, to reduce the import of tomato concentrate, estimated at 400,000 tons per year.

READ ALSO: GTBank, Dangote Cement, others struggle as NSE maintains poor outlook

It is reported that Nigeria is the third importer of the product in Africa, importing from China and some other Asian countries.

After the resumption of operations in March, the company was able to produce only 20% of its capacity due to the inadequate supply of tomatoes.

“We knew tomato is a seasonal crop before we started as it’s the case in China and Europe,” Bloomberg quoted Kaita to have said.

“What we set out to do was reduce the post-harvest loss yearly to feed the factory.”

The farm has already acquired a 5,000-hectare of farmland to cultivate a high-yield variety of tomatoes to supply the factory with raw materials and at the same time introduce the variety to other farms to increase their productivity.

“With this, the output of the farmers would tremendously improve and the processing factory would record ample supply,” Kaita said.

“The effective implementation of the government’s policy in restricting tomato paste importation will guarantee more investment in the tomato value chain, which will eventually lead to self-sufficiency in few years to come.”

In February, Audu Ogbeh, the former minister of agriculture, had said the federal government would ban the importation of tomato paste before the end of 2019.