The theme of Tesla’s highly anticipated Investor Day was about how the leading EV company would be a driver in a global shift away from fossil fuels, towards renewable energy. The lack of a new product announcement seemed to leave investors a bit disappointed and after hours trading saw the share price of the company drop by over -5%.

The event which is usually centered around Musk himself had more cameo appearances from over a dozen other company leaders, this time around. These included the CFO, design chief Franz von Holzhausen, charging infrastructure leader Rebecca Tinucci and powertrain engineering leader Colin Campbell. This strategy may have also been to allay investor concerns about depth of leadership issues during this period that has seen Musk direct a lot of energy towards Twitter.

The presentation also lacked specific details of how the company planned to implement the so called “Master Plan 3”. The event however focused on operational efficiencies and efforts to lower costs in all areas of their operations, areas that investors, traditionally, find interesting.

The list of things not addressed include the recall of their self driving software (which cost customers $15,000), details on their upcoming Gigafactory in Mexico and details on their next generation EVs.

Here are the key insights from the event.

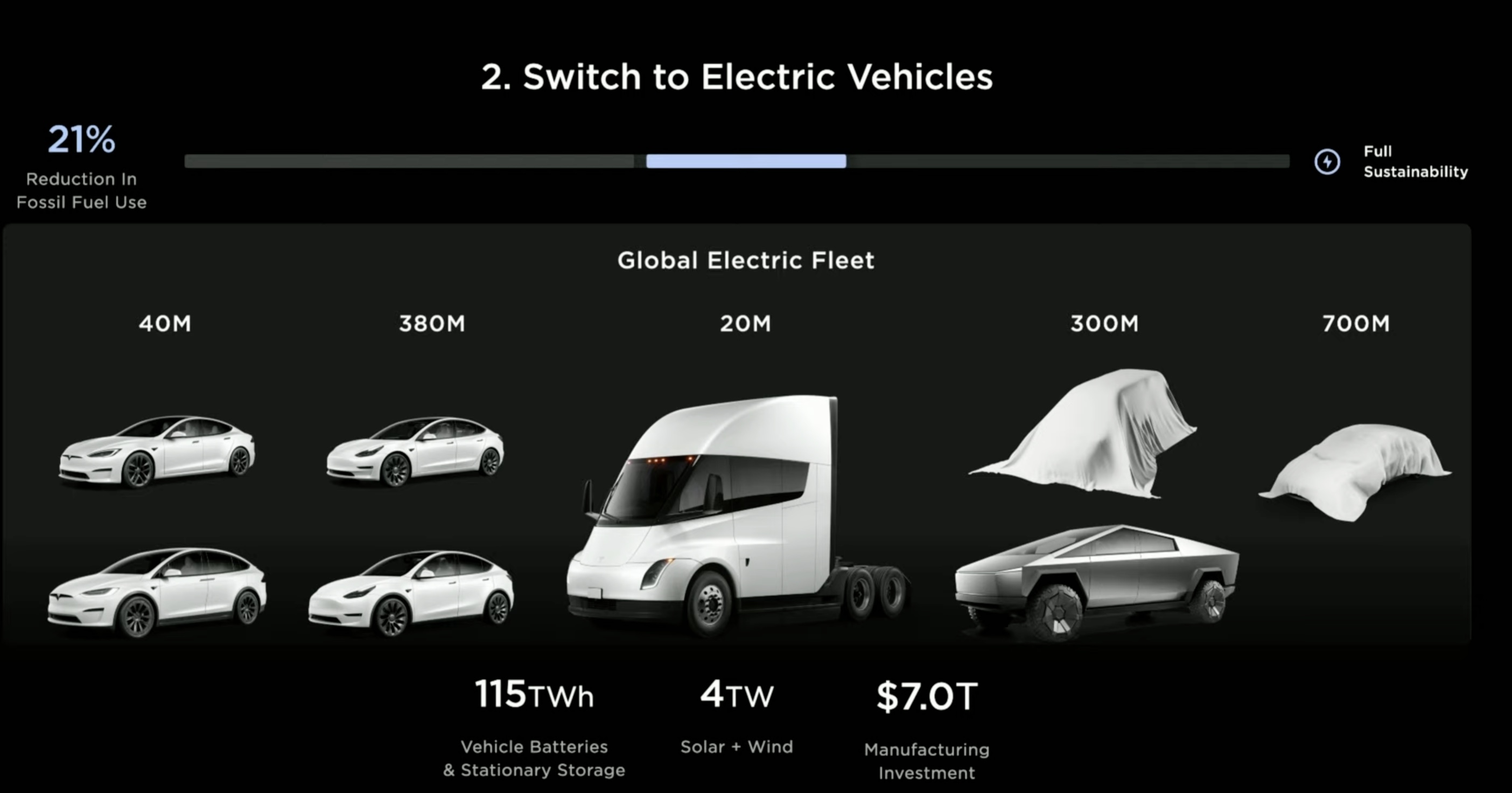

20 million EVs a year by 2030

This is a goal Tesla set several years ago. Several executives, came on stage to talk about everything from manufacturing and raw materials to design, charging and batteries, and how they would actually achieve this.

Tesla produced 1,369,611 and delivered 1,313,851 vehicles in 2022. Toyota, the global sales leader since 2008, sold 10.5 million vehicles in 2022. Tesla would need to increase its production and sales by 15 times.

Vertical integration and slashing costs

Tesla recognized the complex supply chain in the automotive industry and revolutionized the industry by using vertical integration. For example it makes it’s own batteries and even its own seats.

That message continued at the investor event, with executives discussing different pieces of the vertical-integration goal. Tesla has brought in house already, including building its own chip. But the company has continued to push the bounds of vertical integration, right down to the software it uses for in-house operations. Execs said that recently that got rid of an outsourced software for recruiting to use its own and that it developed its own purpose-built microprocessor for high-power electronics that will reduce costs by half.

For Tesla, vertical integration equals cost reductions. And that’s one of the big aims to achieve that bigger mission.

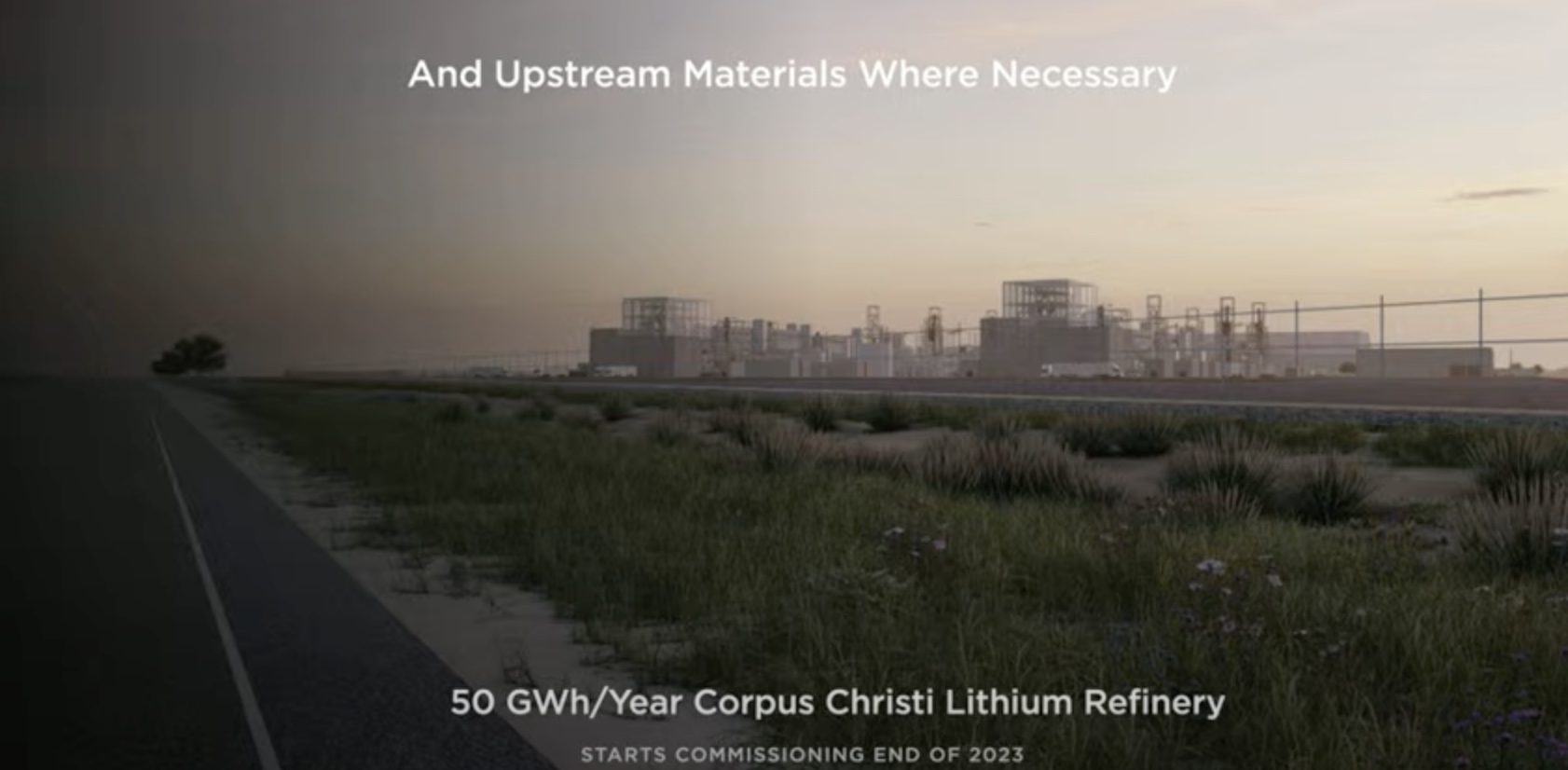

Lithium plant in Corpus Christi

Tesla vertical integration drive extends to the materials it uses in battery cells.Tesla officially broke ground at a new lithium refinery in Corpus Christi, Texas, Drew Baglino, senior vice president of powertrain and energy engineering, confirmed during the event. There is a shortage of Lithium, as EV makers lack competitively priced long range lithium batteries needed to produce enough vehicles to meet consumer demand.

“This is a good example of something where we’re basically talking about breaking ground and and starting commissioning within 10 months and with actual production within 12 months,” Baglino said. “That’s the target.”

Musk added later, during a Q&A session, that a cathode processing facility will eventually be built adjacent to the lithium refinery. He also noted that the company would prefer if others took on lithium mining.

“We’re doing it because we have to not because we want to,” Musk said.

Mexico factory

Mexico President Andrés Manuel López Obrador technically broke the news Tuesday, but Musk reiterated the announcement without sharing any new details aside from a rendering.

“We’re excited to announce that the next Tesla gigafactory will be in Mexico near Monterey,” Musk said. “We do want to emphasize we will continue to expand production at all of our existing factories, including California, Nevada, here in Texas, Shanghai, so we intend to increase production at all factories. So the Giga Mexico would be supplemental to the output of all the other factories.”

Musk went on to tease a grand opening event at the factory.

Next-gen vehicles

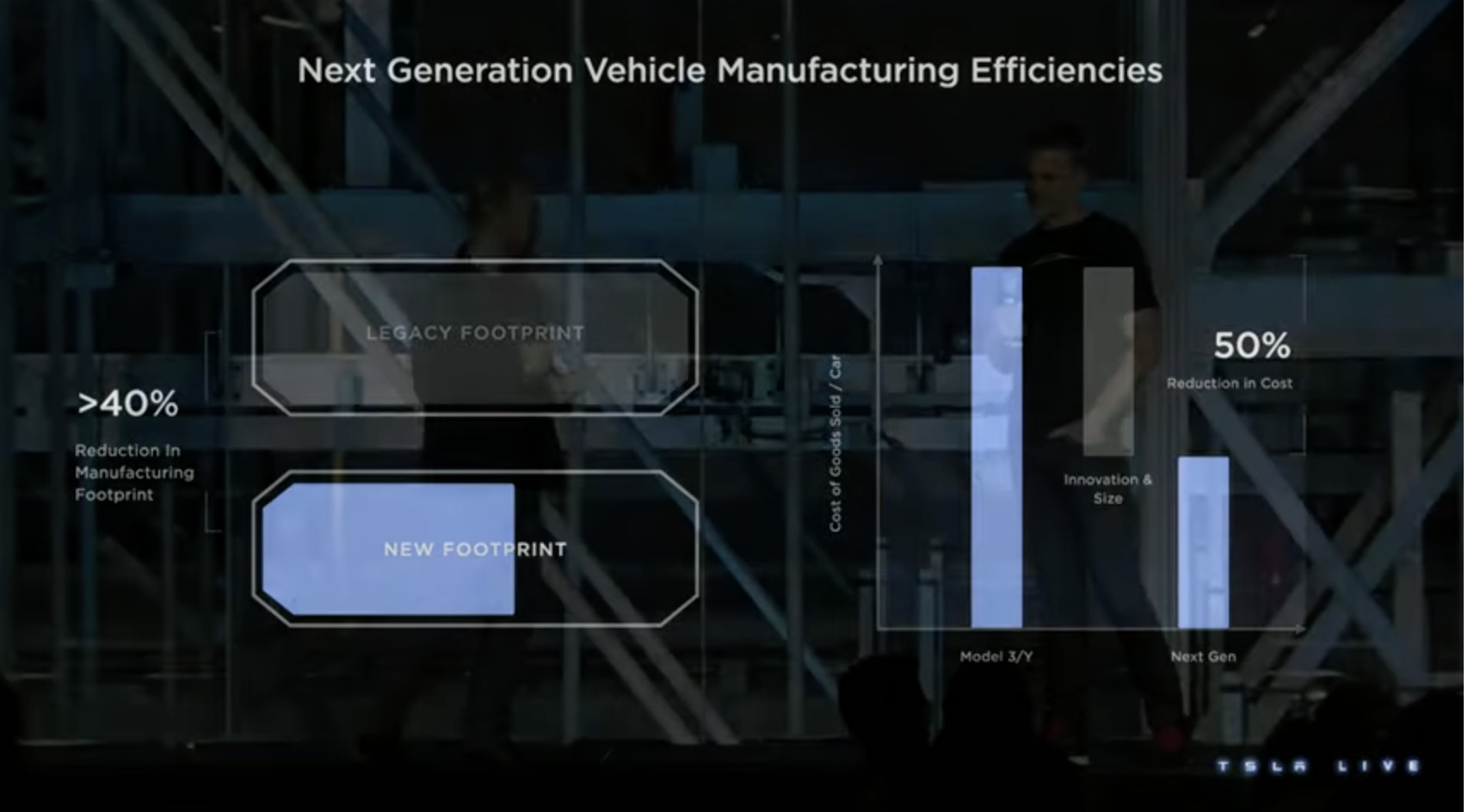

Tesla displayed two veiled vehicles during the presentation, hinting at how it will build its next-generation of vehicles on a completely different platform design. A big part of that design is building in a way that relies on automation to scale faster and cheaper.

“It’s going to look something like this where we build all the sides of the cars independently, we only paint what we need to, and then we assemble the parts of the car once, and only once. We put them where they need to go,” Baglino said.

Baglino noted that this would mean more people and robots having the space to work on separate pieces of the car, rather than lugging heavy objects to a central build-out. What that looks like on the factory floor is sub-assemblies, wherein the front, rear and floor with seats are assembled separately, and then put together at final assembly.

“To increase the scale of adoption of electric vehicles to the orders of magnitude that we just showed you, we have to make constraints part of the solution,” he said. “It leads us to greater than 40% reduction in footprint, which means we can build factories faster, with less capex and more output per unit dollar.”

While that theoretically sounds neat, factories are dangerous places and when more people work in closer quarters, injuries can happen.

Neither Baglino, Musk nor head of design Franz von Holzhausen gave additional details on next-generation vehicles.

Weaning off Rare Earths Metals

As part of Tesla’s next-gen design, the company is developing a new drive unit that it says will be more scalable, in large part because it will eventually eliminate the use of rare earth materials.

“We have designed our next drive unit to use a permanent magnet motor to not use any rare earth materials at all,” said Colin Campbell, VP of powertrain engineering, noting that the new drive unit cost has been reduced to $1,000. Those savings could, in theory, be passed onto the consumer to make for a more accessible, affordable EV.

Tesla said its next powertrain will also use 75% less silicone carbide without compromising performance or efficiency of the vehicle. The new powertrain is also compatible with any battery chemistry, which will give Tesla more flexibility in battery sourcing, said Campbell. Finally, Tesla’s new powertrain factory is apparently 50% smaller than the current one in Austin, which Campbell said means faster scaling of EV production.

Heat pumps

The third part of Tesla’s Master Plan Part 3 is to switch home, business and industrial heating to heat pumps. Musk said at some point Tesla might consider building heat pumps for the home to help solve the problem of the ill effects of traditional heating systems.

Charging and energy storage

Tesla formally introduced Magic Dock, an upgrade to Tesla’s charging stations which opens them up to vehicles that aren’t Teslas. Rolling out the tech will enable Tesla to tap into billions in federal subsidies.

Tesla also said it will add a $30 “unlimited overnight home charging” plan to Tesla Electric in July. An invite-only electric plan, Tesla Electric is exclusively available to Powerwall havers in parts of Texas where retail choice exists. Tesla added that it aims to expand its electric plan into other areas — “market by market, in the same way that we’ve approached Tesla insurance.” The company offered no specific dates.

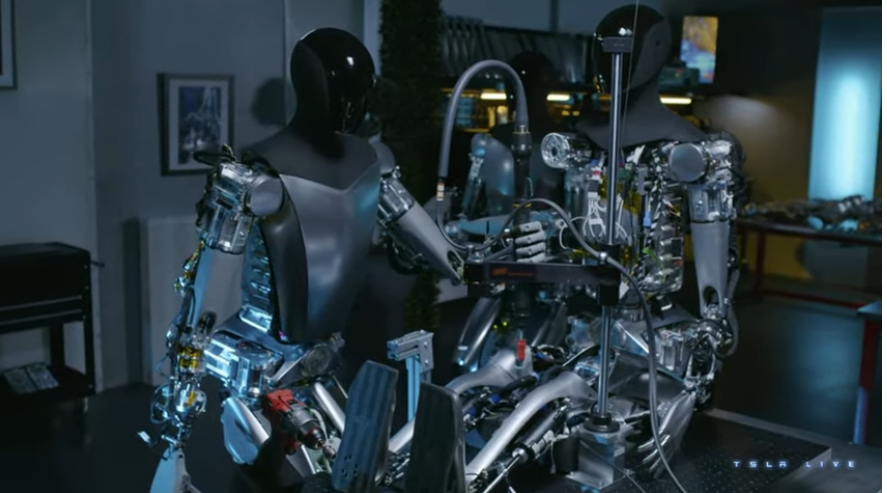

Robot

Optimus the robot was back in the spotlight, with a video showing two robots slowly building another bot.

Musk reiterated that Optimus will be worth significantly more than the car side of things. Optimus is trained using the same AI that trains Tesla’s Autopilot and FSD, and Musk detailed how even much of the hardware for Optimus is taken from Tesla’s cars.

“The actuators in Optimus are all custom designed Tesla actuators,” said Musk. “We designed the electric motor or the gearbox, the power electronics, obviously the battery pack and everything else that goes into Optimus. The same team that designed the groundbreaking electric motors that are in the Model S Plaid designed the actuators in the robot.”

What this means, said Musk, is that Tesla has the tools to bring an actual humanoid robot product to market at scale. Now it’s just a question of timing. And also, apparently, of what the ratio of humans to humanoid robots will be. Musk reckons it’ll be greater than one-to-one because the robots can be used at homes, in industrial use cases and more.

Stock Price Action

Our price projection for $TSLA remains the same as explained here. The situation on the weekly chart still looks primed for a $32 rally to around $240/share